“Those who’ve recently ordered pre-assembled bikes from industry giants like Specialized, Canyon, Trek and many others may still be waiting another year to receive their bike.”

At the annual Eurobike conference where cycling industry leaders from around the world gather to talk all things cycling, a common topic was rife among the experts: More than two years into the pandemic, the global components shortage has left bike retailers without the ability to sell complete bikes. Stemming from this, other issues like factory closures and disruptions as well as the unprecedented spike in bike orders during the height of the coronavirus pandemic have contributed to the supply chain challenges.

No other period than the last two years has the industry been met with such overwhelming demand. Since 2020, as people around the world were told they’d need to be staying indoors due to strict lockdown laws, sudden thoughts of how that’ll affect their fitness or boredom levels arose. However, the demand for bikes and accessories was met with a gigantic red stop sign. Governments across Europe and Asia, where bike components are primarily manufactured and more importantly shipped from, reluctantly had to make the call for factory closures. As Mike Sinyard put it, founder of Specialized bikes, 99% of a bike can be complete, but if one small part is missing, the bike cannot be shipped. This has resulted in a backlog so long, it could take 12-24 months for a customer to receive their bike order.

Expected growth rate of 8.2% per year globally from 2022 to 2030

Despite the delays customers are experiencing in receiving their bikes, the industry is projected to continue growing at a growth rate of 8.2% per year globally from 2022 to 2030. In the US, expected growth will follow a similar trend.

How does this affect the likes of Specialized’s new pre-assembled bikes range for home delivery?

As of February 2022, Specialized launched two new ways that customers can purchase bikes: Firstly, the Ship to Home program allows people to order a pre-assembled bike and have it delivered to their homes. Secondly, a Specialized Delivery program lets customers purchase a bike off the website and a local Specialized retailer delivers it to their door and gives you technical support in setting your bike up. Both of these shopping options require the bikes to be fully assembled, needing every last nut and bolt for completion. Specialized’s Vice President, Robert Margevicius said in March of last year that although they have experienced a 35% surge in bike orders, lead times have been exacerbated from 30-60 to 300-400 days for certain parts like the wheels, suspension and contact points. If sales are not made on the spot then customers will more than likely get impatient and cancel their order. So, with this in mind, any excitement within cycling companies that may have experienced a large spike in orders, may need to be heeded if customers can so easily back out due to delays.

Even electric bikes, or e-bikes, are not immune to the component shortage. Claire Fleischer, CEO of Bosch e-bikes, said in September 2021 that they “have had a hard time since last year to handle the shortages” and that they “expect these to increase even more in the next 12 to 18 months”.

On the manufacturer’s side, frustration is also felt

One may ask, why don’t manufacturers simply make more parts to expedite the problem? However, this doesn’t solve the other issues along the supply chain route. Japanese manufacturer Shimano, who owns 70% of the market across key components, has factories in Malaysia, China and Singapore which were hit with lockdown measures in 2020 and 2021. However, that isn’t the only speed bump in the supply chain. The rising cost of shipping containers and their scarce availability are causing delays too. Container turn-around times from Europe to Asia are slow due to port congestion in Europe and the US, which is the conclusion of research organisation Fraunhofer Center for Maritime Logistics and Services (CML) who began studying supply chain issues in 2020 with Container XChange when Covid-19 arrived. Containers are spending more than 50 days in the ports of UAE countries, the UK and the US, which delays the containers getting back to Asia to collect more bike parts. In comparison, containers are spending only five days in Chinese ports. Because of this, planning has become nightmarish for bike brands and container companies are taking advantage of the pandemonium by increasing their prices. If companies don’t order a container and a ship in advance, more delays are expected.

On the costs side of things, the price of containers increased almost nine times from 2019 to 2022. In July 2019, one 40 ft (12.2 metres) shipping container cost just over $1,000. In July 2021, the same container costs over $9,000, a cost that will eventually be passed on to the consumer.

Alternative solutions have been used, including air freight, but at a greater expense. With the recent Russia-Ukraine conflict and sanctions placed on Russia by the US, UK, EU and some Asian countries, one would question if this already-strained solution is even an option. Russian aircrafts that move cargo from Asia to Europe have had to halt operations due to the closing of Europe’s airspace to all Russian aircrafts. EU air freight companies like Finnair are also suffering, saying moving cargo between Asia and Europe is much more difficult and expensive when having to move around Russia. Other air freight companies who can fly in European airspace are now more in demand and have increased their charges.

Rail may no longer be a safe or trustworthy alternative as cargo travelling from Asia to Europe largely goes through Russia. Alternatively, Russia may cease train operations altogether.

Some positive trends to look forward to

One-size-fits-all bikes are making a comeback

Before the Covid-19 supply chain issues caused customers to have to choose their second, third or fourth bike choices - or none at all - bike riders could choose between specialised bikes for road, mountains, long-distance or ride trails. Now, bike brands are creating do-it-all bikes for multiple terrains so that you can get the most out of your bike.

An increased interest in e-bikes

More and more bikers or people new to biking are choosing electric bikes to train on or commute with. They’re becoming more affordable, and advances in output, battery life and speed are improving. E-bike sales are growing at such a pace that they may outpace sales for standard bikes in the next year or two.

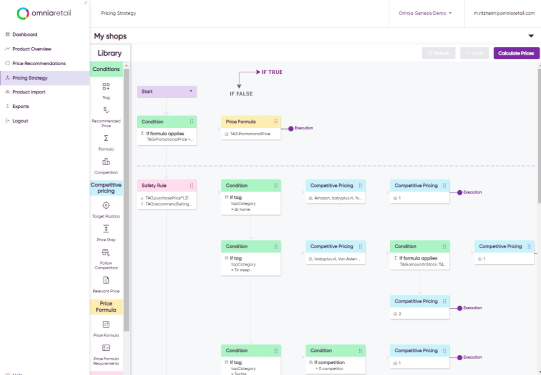

Talk to one of our consultants about dynamic pricing.

What’s in store for 2022 and beyond?

According to bike manufacturers and retailers alike, supply chain issues and extended lead times on bike purchases are expected to continue until the end of 2022, if not into mid 2023. Charlie Revard, co-owner of The Bike Line in the US says that although they have been able to produce hybrids and entry-level bikes for casual biking, their high-end bikes are still sitting without a few components due to supply chain shortages. In fact, a customer wanting a mid-range mountain bike from The Bike Line is going to have to wait until June 2023 to receive it.

As we speak, the aforementioned shipping delays and container scarcity means assembled and ready-to-use bikes are either simply sitting on the ocean waiting to be unloaded or haven’t even reached the container stage yet as their shortage remains an issue. SRAM, a US bike components company based in Chicago, say that they are “producing more product than ever before, but shipping containers are scarce everywhere.” In addition, Michael Zellmann, who is SRAM’s spokesperson, said that not even hiring 500 more employees and spending millions on more equipment has curtailed the bike shortage problem. He added that their factories are working “beyond 100-percent capacity”.

In the meantime, bike riders are going to have to continue using their old bike while they wait for their order but be hyper vigilant about preventative maintenance. Or, riders who want high-end bikes may have to lower their expectations and opt for an entry-level or mid-range bike. Riders also have the options of e-bikes, hybrids or even buying second hand. Online retailers should be vigilant on their stock-based pricing strategies, while brick-and-mortar stores should possibly focus on marketing bike maintenance and servicing to keep people moving through their store. At the end of the day, this is going to be won on the climb.

.png?height=766&name=ORA%20Visuals%2020252026%20(11).png)