If only Henry Ford, the founder of Ford Motors who invented the assembly line that revolutionised how cars are made, could see how corporations have advanced the logistics of supply chains in 2022. Approximately 109 years later, modern supply chains are including engineering and scientific developments like never before, seeing robotics and artificial intelligence (AI) brought to the forefront to increase productivity, decrease overheads, and improve the customer’s experience. With the rapid development of e-commerce and the changing landscape of consumer spending habits, it has become vital for retailers and brands in many industries to rethink and modernise how they bring a product through the process of production, manufacturing, shipment and delivery to the consumer. We have taken a look at how robotics and AI are affecting and improving global supply chains, the companies that run them and their employees.

Robotics in retail and e-commerce

One of the biggest issues within retail and e-commerce is delivery - and fast delivery at that. Using robotics, AI and automation (RAIA) has shown to significantly improve delivery schedules and times. According to a 2021 McKinsey & Company survey, 75% of retail supply chain leaders have made 2-day delivery a priority and 42% are aiming for same-day delivery in 2022. Alongside these consumer demands, 64% of retailers cited digitalisation and automation investments as being critical.

A key area in speeding up deliveries and creating seamless supply chains is warehouse automation, and one such retailer that’s taken on the challenge is Ochama in the Netherlands. The Chinese e-commerce giant JD.com launched robotic grocery stores in four Dutch cities, namely Leiden, Amsterdam, Utrecht and Rotterdam. Groceries and non-food items are collected throughout the store by mobile robots, packaged and presented to shoppers. Customers can order their parcels via the Ochama app and then collect it at the store by scanning a barcode that specifies your order, after which a conveyor belt and robotic arms hand-deliver the order. This is only one part of the machine that has utilised robotics: A warehouse of 20,000-square metres is equipped with automated systems that can process up to 15,000 parcels a day. Because of the technological advancements used in the supply chain, Ochama has brought down the overall costs of food and non-food items by 10%, making the omni-channel retailer one of the first to be able to reduce some of the consumer living costs using robotics and AI.

From groceries to clothing, AI is showing its exponential value. Finesse, a US clothing company, is using AI to determine future fashion trends for potential markets and moving away from fast fashion. When you visit their website, the clothing doesn’t actually exist yet. What you see is 3D-rendered items of clothing where shoppers can vote for an item they’d like to buy. The items with the most votes get made, resulting in reduced overstocking and lower production costs. In this case, we see AI being used as an integral part of the business model instead of being a background assistant to supply chain problems.

AI has shown to be helpful with returns

This particular business model, where votes determine production, doesn’t mean returns and refunds aren’t still an option - or a problem, depending which side of the e-commerce street you’re sitting on. Nonetheless, AI has also shown to be helpful with e-commerce’s biggest headache: Returns. Global e-commerce’s returns problem is estimated to cost €111 billion just over the festive season after December.

Approximately 30% of all online orders are returned by customers, making it a very large and expensive problem. In fact, although a customer may experience the ease of “free and easy returns”, a typical return actually costs a retailer between €19 - €41 each time when they factor in transport, processing (receiving, inspecting, then sorting), and reselling efforts. Berkshire Grey found that processing time could be reduced by 25% and processing costs by 35% if employees could make use of automation and robots.

How may employees view the incorporation of robotics and AI?

A 2021 study published in the Journal of Technology in Behavioural Science conducted multiple interviews with employees of different seniority levels across multiple industries to quantify their understanding and perception of RAIA in the workplace. Firstly, the study found that employees feel that “human touch” and “soft skills” could never be replaced or replicated; secondly, it found that employees should view RAIA as an opportunity and not a threat; thirdly, employees may experience a job satisfaction dilemma; and lastly, employees feel that companies should be extremely prepared before and after RAIA is implemented for whatever the impact may be.

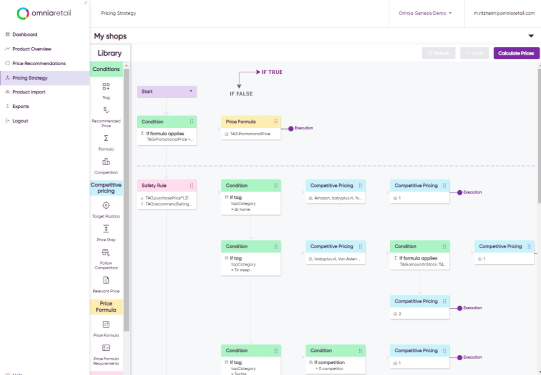

There is no doubt that jobs, workplaces, employee-to-customer or employee-to-employee relationships will change, but it is important for companies and team members alike to start viewing RAIA as a way to upskill, revolutionise and grow. There seems to be a common misunderstanding that by including robotics and AI into the workplace it will automatically result in retrenchments, firings and an exodus of employees. Although we can’t speak for the intentions of all companies, robotics has shown in many cases to improve the work environment for employees. If employees have been spending valuable time on mundane or time-consuming tasks that are part of their job, they can now spend that time on strategy; the very thing that results in better productivity and more profit. With our fully or partially automated dynamic pricing software solutions, Omnia takes a similar stance. Users require less time on repetitive, high-volume tasks and have more time planning and managing the strategic direction of prices.

Looking toward the future

Warehousing, final assembly and production are three main areas where autonomous robots will be the most beneficial. Deloitte predicts that including robotics in these areas can increase productivity; improve the collection of data; and decrease the risk of hazardous tasks while working alongside humans for improved efficiency and safer work environments. McKinsey & Company conducted a study that surmised that 20-30% of the time can be freed up for other important tasks if repetitive tasks are automated or robotised.

Deloitte suggests that using autonomous robots within the supply chain will dramatically increase over the next five years and the more companies start to incorporate robotics into their processes, the more fluid and seamless supply chains will become.

.png?height=766&name=ORA%20Visuals%2020252026%20(11).png)